Validating Thermal Runaway Risk in Process Plants

How can you ensure a chemical process won’t cross into dangerous thermal runaway? This example demonstrates how to model a reactive chemical system and validate safety constraints under uncertainty, by varying initial reactant concentrations to detect early signs of decomposition that could lead to catastrophic thermal escalation.

Model the Reaction System

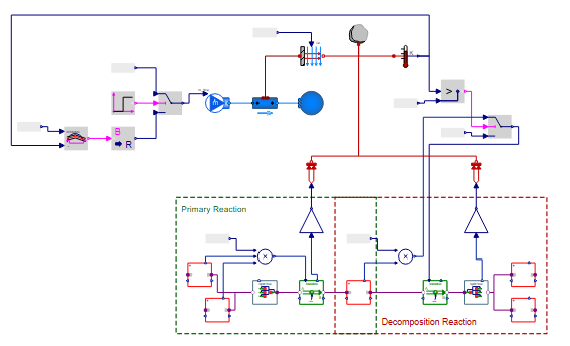

The chemical reaction system is modeled with detailed kinetic equations, capturing temperature-dependent reaction rates, heat generation and cooling mechanisms. The model accounts for real plant constraints and dynamic feedback.

Model of the exothermic chemical process, including a feedback-controlled cooling system used to prevent thermal runaway.

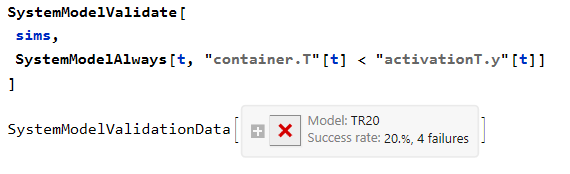

Define the Safety Requirement

To prevent decomposition reactions of the products, the temperature in the reaction tank must remain below the decomposition activation threshold. A formal safety requirement is therefore defined: the temperature must not exceed this threshold across all tested operating scenarios.

Validation results across multiple scenarios, each with different initial reactant concentrations, showing whether the temperature stays below the decomposition threshold.

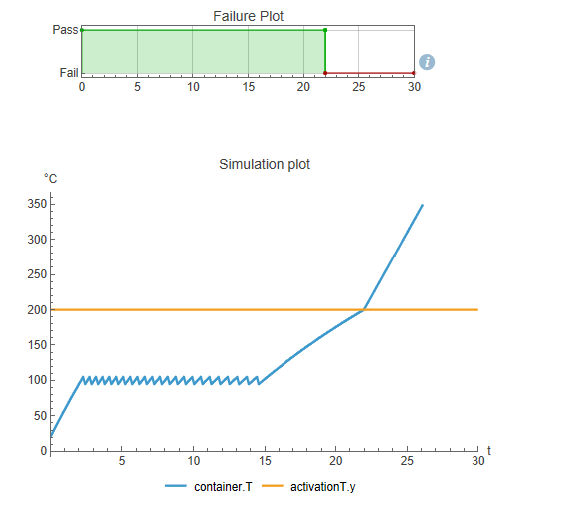

Check Failure Configurations

Retrieve the failure configurations and explore mitigation strategies such as lowering initial reactant concentrations, enhancing the cooling system capacity or adjusting reaction kinetics through catalysts.

Failure plot highlights when the decomposition threshold was exceeded, allowing correlation with key model variables such as temperature and concentration.

Wolfram System Modeler

Try

Buy

System Modeler is available in English

and Japanese

on Windows, macOS & Linux »

Questions? Comments? Contact a Wolfram expert »